Femap

Femap Overview

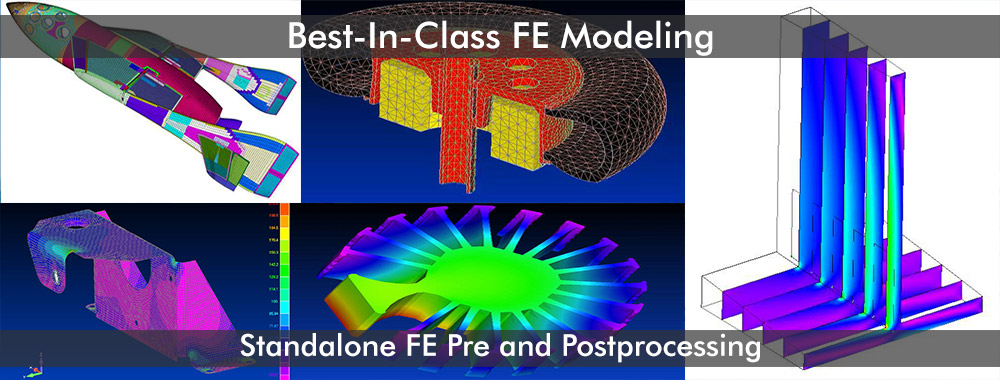

Femap is an advanced engineering simulation software program that creates finite element analysis models of complex engineering products and systems, and displays solution results. Femap can virtually model components, assemblies or systems and determine the behavioral response for a given operating environment.

Using Femap’s digital simulation capabilities you can:

- Predict and improve product performance and reliability

- Reduce time-consuming and costly physical prototyping and testing

- Evaluate different designs and materials

- Optimize your designs and reduce material usage

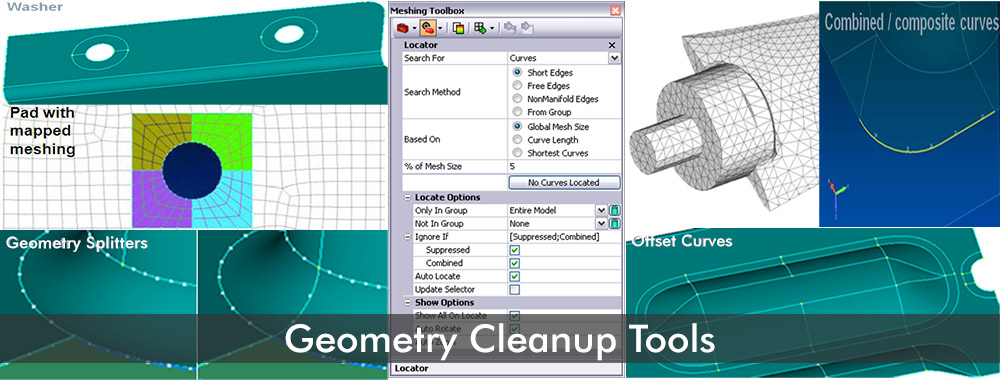

CAD-Independent

Femap is CAD-independent and can access geometry data from all major CAD systems including CATIA, Pro/Engineer, NX, Solid Edge, SolidWorks and AutoCAD. Once imported you can prepare the model for analysis using the geometry locator to identify and display potentially troublesome entities, such as slivers, and either remove them completely with the geometry cleanup tools or suppress them. Femap also offers a wealth of geometry creation and modification functions so you can make necessary model changes in preparation for finite element model creation.

Finite Element Modeling

The full finite element model with underlying data is fully exposed by Femap, allowing you to view, create or modify entities directly. Femap’s grouping, layering and visualization tools help you to manage model display while creating and setting up the finite element model.

Femap includes specialized capabilities to help with modeling tasks including:

- Mid-plane extraction of thin-walled structures to aid creation of more efficient and accurate shell models

- Weldment modeling that connects discrete solid welded parts together into a contiguous model

- Data surfaces that allow you to create complex loading conditions based on prior analysis output for multi-physics applications

Finite Element Meshing

Femap’s 3D solid and surface meshers are tuned to generate high-quality meshes, providing well-shaped elements to ensure accurate results. Femap gives you full control over all mesh generation parameters including mesh sizing, meshing of small features, growth factors, short edge suppression, etc. With complex geometry, modification of the mesh is often required in areas where greater accuracy is desired. For this situation Femap’s Meshing Toolbox allows you to interactively modify mesh sizing parameters on the underlying geometry, and see the mesh update automatically. You can also view element quality feedback live while modifying the mesh, to ensure that a high-quality finite element model is created.

Assembly Modeling

Femap with NX Nastran supports assembly modeling, including automatic contact detection that determines the components initially in contact. The contact regions can be set to be simply in contact (with or without friction) or glued together. The contact calculations performed by NX Nastran are iterative and update during the solution, to take into account deformation changes representing the true contact condition in the final results.

Other types of component assembly modeling techniques also supported include spot-weld, fastener elements, and bolted joints with optional pre-loading.

Beam Modeling

Besides solid and shell element models Femap also supports beam modeling and meshing. This technique allows models comprising long, slender components (for which a solid meshing approach would create a large, unwieldy model) to be represented by one-dimensional elements with associated properties.

Model visualization is key to beam modeling, and with Femap you can view these elements as solid components and include offsets. Femap features a section property editor which includes a library of standard cross-section shapes. You can also define your own sections, and the built-in section property calculator automatically determines the required properties.

Also available are full beam visualization and results display options including shear and bending moment diagrams.

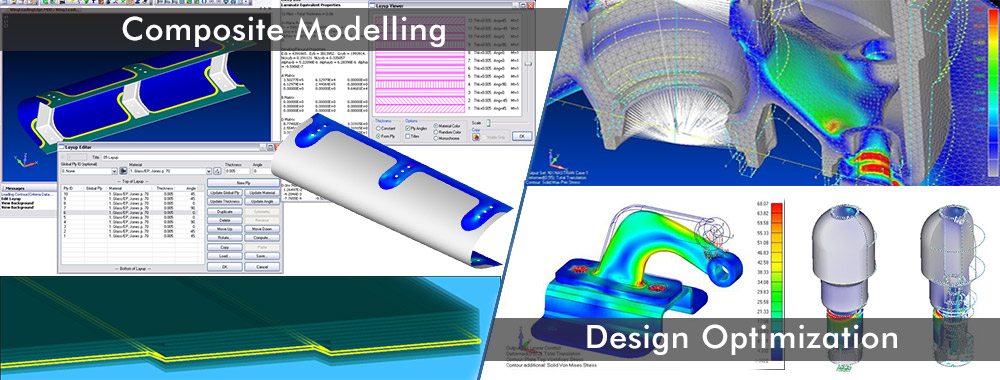

Composite Modeling

The use of composite materials in designs has increased significantly in recent years, and Femap can help you model and postprocess results on composite structures. With Femap’s a laminate editor and viewer, you can update the laminate properties interactively as you create and modify plies in the laminate.

You can also postprocess composite laminate results using Femap’s global composite ply feature, which allows you to view results on continuous plies through the structural model.

Solver Neutral

Femap is solver-neutral and provides in-depth pre- and postprocessing support for all of the main commercial solvers on the market, including NX Nastran, Ansys, LS-DYNA, Abaqus and TMG. You can take full advantage of the advanced analysis capabilities of these solvers using Femap’s comprehensive modeling and analysis support, particularly for dynamic, geometric and material nonlinear, heat transfer and fluid flow analyses.

Post processing

A wealth of visualization capabilities help you view and interpret the results to quickly understand the model behavior. You’ll find everything you need to view and interpret the output data, including:

- Contour and criteria plots

- Deformed shape animations

- Dynamic cutting plane and iso-surfaces

- Full output selection

- XY plots

- Free body diagrams and grid point force balance output

- Time and frequency domain animations

Complete access to results data is provided through the Data Table pane, which you can use to gather, sort and control the amount and type of data that is visible, to compile an analysis report.

Scalable Simulation Solutions

The Velocity Series CAE products offer scalable solutions for design engineers in the form of the CAD-embedded Solid Edge Simulation program, and Femap with NX Nastran for CAE analysts.

The Femap with NX Nastran product line itself offers solution scalability, from the more general simulation capabilities available in the base module to more advanced applications including dynamics, optimization, advanced nonlinear, rotor dynamics, heat transfer and fluid flow in add-on modules.

Customization

Femap’s open customization capability allows complete access to all Femap functions through an OLE/COM object-oriented Application Programming Interface (API), which employs standard, non-proprietary programming languages. Access to the API is through a development environment within the user interface where you can create custom programs that automate workflows and processes, and which can interact and exchange data with third-party programs such as Microsoft® Word and Excel.

Usability

Femap is an intuitive Windows®-native application. Femap’s support of multiple graphics windows and specialized panes, such as the Model Info Tree and Data Table, allow complete access to the finite element model and results data and help promote efficient work flows. You can modify the appearance of the interface to suit your requirements, including repositioning panes, modifying the level of functionality exposed, and complete toolbar and icon customization.

FEMAP – Powering today’s most advanced engineering analysis environment

Best-in-class digital simulation

Why digital simulation?

Industry pressure to reduce costs and improve quality is driving growth in the use of digital simulation throughout the product lifecycle. Choosing the right tools is key to achieving the business benefits of digital simulation.

Why Femap?

Siemens PLM Software’s Femap™ system facilitates an advanced engineering analysis environment. CAD-neutral and solver-neutral technology and cost-effective functionality have enabled Femap to become the world’s most popular engineering analysis environment for Nastran users. It is widely used by the world’s leading engineering organizations and consultants to model complex products, systems and processes, including

satellites, aircraft, defense, automotive vehicles, electronics, heavy construction equipment, lift cranes, marine vessels and process equipment. Femap and NX™ Nastran® software are highly integrated and can be sold together as a bundled solution. But more than this, being open to all solvers, Femap demonstrates the power and value as a core analysis tool. Femap is CAD independent and leverages Siemens PLM Software’s Parasolid® modeling kernel that allows direct access to Parasolid data for surface and solid modeling in addition to advanced geometric tools necessary for accessing non-Parasolid geometry.

From advanced beam modeling, mid-surface extraction and hex meshing to robust CAD import and idealization, Femap gives you unparalleled model control and flexibility with a broad range of loads, materials, analysis types and visualization options. Femap is not just a solid investment for those committed to excellence in the use of finite element analysis technologies. It’s the right tool to help you realize your business goals.

Your business benefits

•Faster to market with innovative new products

• Lower cost through less physical prototyping, fewer engineering change orders and better in-service warranty

•Increased product quality

Femap is recognized as the world’s leading CAD-independent Windows-native pre- and post-processor for advanced engineering finite element analysis (FEA). It provides engineers and analysts with an FEA modeling solution to handle even the most complex tasks easily, accurately and affordably. Femap has embodied the principles of power and simplicity for over 20 years and continues that focus today with a Windows-native graphical user interface and efficient workflows that simplify access to all Femap functionality and streamline the process of creating an accurate and representative simulation model.

As an engineer, you demand software that is not only cost effective and easy to use, but with the power to model the toughest problem. Femap delivers just that – affordable high-performance FEA modeling for the engineering desktop with Windows-native ease-of-use.

Scalable solutions

Powerful, affordable CAE

Femap is available standalone, inside Solid Edge® software and bundled with NX Nastran with add-on modules that form a series of powerful, robust and affordable solutions suitable for companies that have a diverse set of analysis requirements. By providing engineering and design teams with advanced CAE tools, companies enable their engineers to focus on improving product performance and reliability while streamlining the product development process.

Femap with NX Nastran

The Femap with NX Nastran package seamlessly combines the advanced functionality of the Windows-native Femap pre- and post-processor with the powerful NX Nastran solver. Femap with NX Nastran allows engineers access to a much greater depth of analysis functionality to easily and efficiently solve complex engineering problems.

Additional NX Nastran modules

A series of advanced NX Nastran solution capabilities are available as add-on modules, providing engineering desktop solutions for even the most advanced Nastran analysis.

Proven solutions

By leveraging over 25 years of integration effort, Femap with NX Nastran provides direct access right on the Windows engineering desktop to the most complete suite of Nastran capabilities available today. Siemens PLM Software combines flexible licensing and packaging with “fair value” pricing to provide all engineering tool users with an affordable way to access the most advanced Nastran capabilities at an attractive total cost of ownership.

CAD independent

Serious engineering in a Windows environment

Femap delivers a depth of functionality normally only found in more expensive applications. With powerful tools easing all aspects of the creation, manipulation and review of an engineering analysis model, Femap is the natural choice for a complete CAD-independent analysis environment. Femap provides exceptional value and performance and is not limited to geometry-based digital data. Femap will also delight customers working with pure finite element model data. As a nuts-and-bolts, “bottom up” finite element pre- and post-processing solution, Femap provides a range of FEA model readers to rapidly import existing models from many FEA solvers. Advanced functionality then eases manipulation of finite element data at the node and element level.The bottom line is that Femap makes it possible to quickly create models that accurately predict the structural, dynamic and thermal performance of single components, assemblies or complex systems.

CAD independent

Femap offers seamless geometry access with major CAD systems such as Pro/Engineer, Catia, NX, NX I-deas™ software, Solid Edge, AutoCAD and SolidWorks. Based on the industry- standard Para-solid geometry engine, Femap offers extensive geometry creation tools including standard wire-frame curves, surface and solid modeling. Powerful shelling, blending, Boolean operations, surface imprinting and lofting combine to make Femap extremely effective at creating geometry for analysis.

A better mesh, faster than ever

With fully automatic, high-speed tetrahedral solid meshing and quad- dominant surface meshing technology, Femap creates fast and accurate meshes easily and reliably. You can also take over full control and work interactively with Femap to manipulate the mesh or underlying geometry, while viewing element quality feedback live.

The right geometry for analysis

Engineers often encounter geometry that is not ideal for analysis model definition. Femap provides geometry creation and editing tools for curves, surfaces and solids, feature suppression and mid-surface extraction. Solids can be subdivided and automatically connected to represent dissimilar materials or to facilitate semi-automatic hexahedral mesh generation. Engineers can combine multiple surfaces to improve meshing areas for higher quality shell meshes.

Automatic assembly management

Femap can automatically detect components of an assembly that are in contact. The method of connection, whether glued or contact (linear and nonlinear) is easily specified allowing rapid setup for assembly models.

Solver independent

Integrating analysis technologies

Leading firms recognize that a single analysis technology seldom meets all their requirements. By integrating multiple analysis technologies in a single modeling and visualization environment with Femap, they can make better design decisions faster.

Analysis set manager

The analysis set manager in Femap allows you to store solver setup data with your models, so you don’t need to complete numerous dialog boxes each time you edit your model and create a new analysis input file. The sets can also be saved in a library for use with other models.

Multiple solver support

Femap provides in-depth, high-quality support for industry standard solvers, including the popular and proven NX Nastran, MSC/MD Nastran, Abaqus, Ansys, MSC.Marc, LS-DYNA, SINDA and TMG. Femap provides the ability to re-use and integrate analysis models from legacy data as well as from customers and suppliers. The complete Femap element library, with comprehensive support of physical and material definitions, takes full advantage of the advanced capabilities of these solvers, including dynamic, geometric and material nonlinear, heat transfer and fluid flow applications. Leading third-party solution providers use Femap to perform CFD, soil modeling, advanced thermal analysis and electro-magnetic simulations.

Fully customizable

Integrated BASIC API Programming Environment

Femap offers a full-featured BASIC development environment in a separate window. Directly from the Femap user interface, you can access the OLE/COM object-oriented Femap application programming interface (API) that provides direct access to all Femap objects and functionality. The BASIC engine is fully OLE/COM compliant and can interface with Femap as well as any OLE/COM compliant program such as Word or Excel. You can create custom programs that automate repetitive tasks, search model or results data, or programs that transfer model information to Word or Excel to create customized reports. Many useful programs are delivered with Femap in an ever expanding library, and can be found in the Custom Tools toolbar right in the user interface. These powerful customization capabilities allow complete access to Femap full functionality through standard nonproprietary programming languages, and maintain Femap as the industry’s premier independent and open engineering environment.

Macro program files

In addition to the API programming capability, Femap hosts a Program File capability in its own Femap window. User-defined macros can be recorded, edited, debugged, and played back all within the Femap interface.

Flexible solution configurations

Femap with NX Nastran

Provides all of the capabilities that you will need in many instances, including linear statics, normal modes, buckling, steady-state and transient heat transfer, basic nonlinear, design sensitivity and unlimited problem size capabilities.

Dynamic response

Enables product performance to be evaluated in both the time and frequency domains.

Optimization

Determine optimal design parameters with sizing optimization capabilities.

Rotor dynamics

Predicts the dynamic response of rotating systems such as shafts, turbines and propellers to determine critical shaft speeds.

Advanced nonlinear

Facilitates large deformation; supports nonlinear materials, time-dependent loads, deformable and rigid contact. Provides nonlinear time integration for impact analysis.

Structural analysis toolkit

Saves postprocessing time by organizing results data and calculating additional results quantities.

Aeroelasticity

Determine structural response from aerodynamic loading for static and flutter conditions.

Integrated multi-physics solvers for Femap

Femap Thermal

Femap Thermal includes both the transient and steady-state thermal analysis capabilities required to solve a majority of common engineering problems. Capabilities include the modeling of conduction, convection, radiation and phase change. Femap Thermal provides a range of thermal boundary conditions and solver controls as well as a powerful thermal modeling tool for assemblies. This thermal coupling capability allows users to create paths for heat to flow between parts in large, complex assemblies.

Femap Advanced Thermal

Femap Advanced Thermal adds many advanced thermal and fluid flow modeling capabilities to the Femap Thermal package. For example, fluid duct flow modeling includes coupled convection and fluid flow analysis. An extensive set of tools for advanced radiation and spacecraft modeling includes solar and orbital heating, orbit modeling and display, specular reflections with ray tracing and articulating structures. Femap Advanced Thermal also provides advanced solver features such as custom user subroutines, model simplification, substructuring and interfaces to industry thermal codes.

Femap Flow

Femap Flow provides a comprehensive 3D computational fluid dynamics (CFD) solution fully integrated within Femap. When combined with Femap Advanced Thermal, it solves a wide range of multi-physics problems that involve fluid flow and heat transfer. Both low- speed and high-speed compressible flows can be modeled. The Femap Flow solver uses an efficient and robust element- based finite volume, multi-grid solver to compute 3D fluid velocity, temperature and pressure for both steady-state and transient applications. Forced flow, natural convection and mixed flows can be modeled with multiple inlets, outlets and internal flow boundary conditions. For electronics cooling applications, the package easily models fan curves, inlet and outlet resistances as well as convection from thin structures. Rotating systems, moving walls, flow turbulence models, humidity and other features are available for the most advanced fluid flow modeling requirements.

The Siemens PLM Software advantage

simulation applications are part of a broader portfolio that empowers development teams at the world’s largest OEMs as well as thousands of the world’s smaller companies. Value depends on the ability of solutions to scale, ensuring the right software is available to the right people and that specialists can leverage the work of the much wider development team. Throughout its product portfolio, Siemens PLM Software leverages key attributes that help companies achieve business objectives such as waste reduction, quality improvement, shorter cycle times and greater product innovation. These unique attributes directly support business process initiatives aimed at transforming product development:

Managed development environment: Full integration, synchronized management of all product data and process knowledge to transform product development with a structured collaborative environment.

Unified product development solution: Seamless integration of applications to rapidly propagate changes of product and process information, replacing point solutions with a unified development system, from concept to manufacturing.

Knowledge-driven automation: The application of product and process knowledge across all elements of product development to automate processes and maximize re-use.

Simulation, validation and optimization: Comprehensive simulation and validation tools to automatically check performance and manufacturability at every step of the development process for closed-loop, continuous, repeatable validation.

System-based modeling: Structured conceptual models standardized design practices that allow rapid creation of variants, transforming development from component-based design to a systems engineering approach.